-

Posts

909 -

Joined

-

Last visited

-

Days Won

151

Content Type

Profiles

Forums

Events

Everything posted by Garrison Joe

-

This Artful Bullet article shows some good pictures of the three common 1911 lip designs. https://www.artfulbullet.com/index.php?threads/1911-magazine-feed-lips.9672/ Magazines with lips which uniformly narrow for the full length from the back plate of the magazine up to the release point of the round - those are THE BEST for a "round ball" load. That was what was provided in both WWs to shoot military ball. Often called GI-Ball or tapered lip design. Magazines with wadcutter type lips, also called controlled feed lips, usually have a good chance of feeding non-ball loads. Especially made for short stubby nosed wadcutter loads for target shooting. These wadcutter loads will often pop up the round too fast in a military (tapered) lip mag and lead to point-up jams against the feed ramp. The wadcutter lips are usually parallel at the rear for a short way, then open to a clean release of the cartridge at a specific point engineered for best feeding of wadcutters and the stubby hollowpoints. Most good quality magazines today are made as the hybrid design, combining a shorter taper section at the rear, and then an opening of the lips which allows almost the same type of controlled feed of the wadcutter magazine. Like Boggus, I like a magazine with hybrid lips for Wild Bunch, especially with bullet designs other than a 230 grain round nose. Hybrid lips give the most reliable feeding with a wide selection of bullet shapes and compositions, in my experience. good luck, GJ

-

Mine run 15 recoil, 19 main. You can easily tell if you're sprung correctly. Fire a couple mags of your match ammo from one spot. Look for the center of the pattern of ejected cases. Step that off from your shooting position. If closer than 5 feet, you are sprung stronger than needed. (results in harder slide pull than needed, and can get to where you get a failure to eject) If pattern is more than 10 feet away, you are too lightly sprung (can batter the frame and slide). And the recoil and main springs usually "balance with each other" best with the recoil being about 3-4 pounds lighter than the main. The mainspring bore in the grip housing often needs honing to remove the roughness from factory machining. good luck, GJ

-

Simple answer is - yes, a 38 Spl rifle will be legal, especially since you already have it. And - Yes, current PF minimum is 60 for Rifle. If you need to access the handbook - it's at: SASS Rule Handbooks page Welcome to WB! GJ

-

Model 25 is not legal (currently). If you can run a "short mag tube" shotgun with some single-loading required, go for it. You will likely be slow on a 6 shell stage. good luck, GJ

-

Not legal, if they extend below the frame. Can you return 'em? Good thing to read the rules before buying, or attend a match, or even ask here. Buy good quality mags - 1911 is a finicky gun with the wrong combination of ammo and mag and then perhaps a factory stock (non-tuned) gun. With Tripp mags I can run almost any ammo. Colt, most. MANY other mags - always a problem of some sort. good luck, GJ

-

Considering the fact that the current administration is trying to attract shooters to Wild Bunch who refuse to buy a 40 caliber or higher gun, or even load a heavy factory type load in .38 special, I'd say the politics would prevent it. Even if it would be ballistically feasible. GJ

-

Hmmm, 20% of the shooters were dangerous enough to earn a SDQ or two? Seems to say there needs to be MUCH better introduction of new shooters to the safety precepts common to all kinds of action shooting, but especially with the 1911. None of our SDQ penalties are for a trivial safety malfunction by shooter, except for shooting out of category. good luck, GJ

-

You answered your own question there, EC. Yes, a good load like that CAN work in a .38 special case if you "shoot for" the 150 PF target. GJ

-

There is NO standard course of fire for Bolt Action Military matches (BAMM). The match director, if they are being shooter-friendly, should publish the course of fire that they have decided to use with any match invitation. That way, the shooter can come with proper ammo and any other equipment that may be allowed. Shooting a few BAMM matches is the best way to find out how to put on one. Not everyone has that much ability to travel to the bigger Wild Bunch matches where BAM matches are held (like EOT or Land Run, for example). Yes, I have set up up at EOT as a BAM match director. So - I'll describe the general approach I've seen at four different venues, and used for EOT. BAMM is usually considered to be a "combat-shooting" match, using, of course, WW II or earlier military rifle designs. Because many ranges have no more than about 100 or 200 yard bay lengths, the setting of targets out to those distances is common. Shorter than 60 yards or so, usually is not considered much of a challenge other than just working the action and reloading. Use of fairly strong targets and stands is needed, as a military rifle of those times can throw a cast bullet of 150 grains or so at up to 2000 FPS. Jacketed bullets usually are not allowed due to damage to all but heavy armor steel plates, and the facts that folks love to hear the targets ring and don't like tramping down 150 yards to patch paper targets, or reset heavy knockdown targets. Since some of the "poster boy" rifles for BAMM are Mauser 98s and Springfield 1903 designs, and they have 5 round built-in magazines, usually the match consists of shooting 10 or 15 rounds in sets of 5 shots, which will take about 40 to 60 seconds, usually with the reloads "on the clock". If possible, target distance is varied to encourage understanding use of sights and hold-offs. Sometimes using shooting sticks or benches is allowed, but some of the more fun matches either shoot all rounds off-hand unsupported, or use a variety of standard military shooting positions, like kneeling, sitting and off-hand. Prone, not so much if you will require shooters to get into position and recover after shooting, all while on the clock (consider your shooters' physical capabilities). Scoring is USUALLY like most long-range rifle matches - number of hits during the run, with ties decided by lowest time to get those hits. I've shot in one BAMM that scored it like a main-match stage (lowest time after adding in penalty times for misses), but then the match rewards speed over accuracy (which was not the design purpose of bolt action rifles - to "Project Power At Distance"). So, because of a variety of potential course layout, number of rounds fired, target distance, shooting positions and even the scoring method, now you may understand why you want to publish the course of fire to be used AHEAD OF THE TIME THAT FOLKS TRAVEL TO THE MATCH. However, I've not seen one yet which accomplished that. So plan ahead. I usually take at least 50 rounds of ammo loaded to 1800 FPS to a BAMM, a rifle that I have sighting dope for 50 to 200 yards (even 300), several stripper clips, shooting sticks, a mat, and a spotting scope. One of the biggest deterrents to getting good attendance at BAM matches is the need for shooters to reload fairly accurate, rifle caliber, moderate power cast bullet loads - not something many folks know how to do. And commercial ammo loaded like that is real hard to find. Even if the venue has a suitable bay or rifle range and strong steel to shoot BAMM on. good luck, GJ

- 1 reply

-

- 2

-

-

Yes, that SASS alias rings a bell with me. A few years back, I used to see it in some of our forum discussions. If I remember correctly/ A SASS Alias name is requested by a member as part of their shooting personna. If the requested name meets SASS guidelines and is not registered as a SASS alias yet, the SASS office assigns the requested alias to the member requesting it. Then, when they shoot or converse here on the Wire (forums), the alias name is used rather than real names. Never have heard of a family member asking about an alias being assigned to one of our members. If you have a serious concern, then you should contact the SASS office by email or phone. good luck, GJ

-

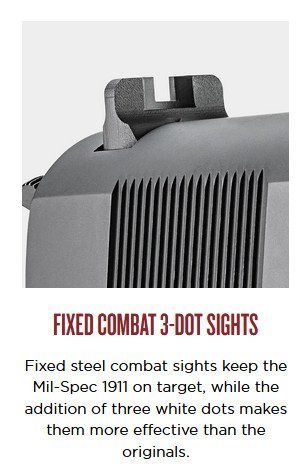

Getting rid of white dot sights

Garrison Joe replied to Bullseye Bracc's topic in The Wild Bunch Wire

Sure, that Springer MilSpec is a Traditional compliant rear and front sight when the 2 dots on rear and 1 on front are blackened. As per above, lots of folks use a sharpie. Same as has been done on the original Ruger made SR 1911 good luck, GJ -

Gun Problem - Extractor Problem - Reloading Problem - Or ???

Garrison Joe replied to JJ's topic in Reloading for Wild Bunch

The case is being slammed into the slide wall during ejection, probably around the ejection port opening. This is very common when the geometry (shape) of the extractor (which you just changed) is not yet fitted to your gun. The dent comes from impact, while the sideways scratches are caused by the high-speed "twist" imparted during ejection as the case is pulled on the right side by the extractor hook and hit in the left lower rear by the ejector. Look for where there is a shiny spot of "brass rub" on the slide. Often it's on the lower side of the ejection port. But some times in other locations. There is more work to do when fitting a new extractor than just setting the tension. One of the best but short descriptions that I have found is here, written by Bill Wilson: https://www.m1911.org/technic2.htm Look at the very last diagram very closely. If you understand all of the angles and beveling he shows, you may not have to do more study. OK, so you probably do not understand why he is so particular about EVERY facet (machined cut) shown on that extractor tip. So, read this one next, and SEVERAL times, as it is pure gold! https://www.1911forum.com/threads/steve-in-allentown-extractor-fitting.829865/ And the extractor section of John Marshall's instructions: https://sightm1911.com/lib/tech/reliability_secrets.htm He makes this statement that speaks volumes about just "slapping in " any company's new extractor: "Most factory extractors and many aftermarket extractors need attention to achieve the optimum in reliability." OK, the lazy way to solve cases hitting the slide, is to cut away the slide where the shiny brass impact spot shows up. The "lowered ejection port" found on lots of 1911s from the factory is this kind of fix, whether a gun really needs it or not. Opening the ejection port like that lets a factory get "no contact" ejection without having to do special fitting. John Browning did not think that it was necessary - his slide designs did not use a lowered ejection port. Case denting was fixed by hand tuning the extractor tip to turn loose of the case rim so that the case ejects straight out to the right, or even upwards at 2 o'clock. I'm sure you have seen 1911s that toss brass straight up to land on the shooter's head, as well. That too is due to a poorly shaped extractor hook. A tighter grip on the case by the highest part of the hook will pull the case out high (12 to 2 o'clock). A tighter fit on the case rim down low in the hook pulls the case out so it slams into the slide wall under the ejection port. Also, check that you have the firing pin stop fitted so that the extractor is not twisting in it's bore. A problem called clocking. Can cause the extractor to turn and hold onto the case in a deleterious manner. Also, look for severe gouge in the extractor cut of the fired cases. A sharp or poorly shaped extractor hook will put a "horizontal gouge" in the angle part of the extractor cut. good luck, GJ -

My take on your plans so far - Buy a belt suitable for your holster with NO loops sewn into the belt. Then you can experiment with buckling in front, or buckle spun to the back. A cartridge holder for at least 2 rifle reloads and at MOST 4 shotgun shells works just fine, because you can almost always start with 6 shotshells in your gun (unless you plan to shoot a side-by-side, then I'd suggest you immediately get a shotgun belt holding 10 shells (paired together) as well as the gun belt). And you might as well get 3 paired 1911 mag holders, total of 6 mags. Lots of matches shoot more than 28 pistol rounds on a stage, and you need a spare mag in case of fumble, misfeed, jam, etc. All your magazines then will come to hand the same way (height, angle). Some folks like wearing huge award buckles on their belt, and they are almost always in the back, for the AUDIENCE to see. And when worn in front they take over valuable "belly space" that is better used by ammo of some kind! Get a stout belt made for holster carry. Light belts will move around, break, sag, and holsters and holders need to stay put, too. Best results usually come from using same maker for belt and holsters and holders. good luck, garrisonjoe

-

In Wild Bunch Shooter's Handbook, no mention is made of pocket pistols. I would GUESS that if a match is offering to have some sort of pocket pistol side match, they will have to define what guns they will allow and how troopers will shoot it. The SASS Range Operations and Match Director Guide - Wild Bunch Action Shooting is not currently available on the SASS home site, or I would have searched through that. If you know of matches that are hosting a P P side match for Wild Bunch shooters, you might mention what match that is. Right now, AFAIK, pocket pistols is an official side match only on the Cowboy side of the organization. good luck, GJ

-

Declaration of a gun malfunction should mean there should be greatly increased attention be paid to the gun and the shooter's attempt to unload it. Not the range safety officers (perhaps including the unloading table officer at the time) ignoring the shooter's situation and leaving it to him to make a really bad safety move. "Malfunction" is called on the line to relieve the shooter of having to try to clear the gun on the clock to be able to continue. Shooter can even declare that themself. Also, it alerts the line workers that the gun needs special attention to get it to the unloading table safely, without the shooter carrying it, worrying about it, perhaps even trying to jiggle the action. And, of course, it relieves the shooter from the penalty of restaging a gun that is in an unsafe condition for normal restaging (loaded or cocked hammer on live round), so that they can continue shooting the rest of the stage. Then at the unloading table, it needs special attention to note what failure condition and how many unfired rounds are in the gun, and then attention to returning the gun to good function safely. Nothing in that awards a free pass to commit unsafe acts with that gun. Unsafe acts with a still loaded gun just magnifies the safety risks. Declaring a Malfunction is not a penalty, it's a notice to the posse that the shooter will not be trying to fix a problem with the gun on the clock. good luck, GJ

-

It's just as dangerous as if NOT declared a malfunction. There should be no "free pass" here when a potentially mortal or serious injury could result. IMHO. The rules establish the stage firing line with a 170 degree downrange direction required to be able to fire any of our firearms. That eliminates most loading and unloading tables right there as being places where a gun can be fired for any reason, and maybe as a last resort, to clear it. This gun was declared malfunctioning. But for the shooter themselves to go ahead and try to fire that malfunctioned gun, without range safety officers attending? And without successfully determining what caused the malfunction? That is, generally, insanity. It's trusting to hope instead of finding and being sure the problem with the gun has been corrected. Did declaring the gun malfunctioned mean the gun would not fire? Not in this case! This particular case sounds to be an INTENTIONAL firing. Not an accident while trying to empty the gun and somehow getting an unintended firing because of lack of knowledge, lack of care, or a mechanical problem, all of which should have been avoided by an experienced range safety officer taking charge of the malfunction. good luck, GJ

-

BTW, every WB (and Cowboy) match needs access to a squib rod to assist the shooter with clearing stuck rounds or squibbed bullets! Lengths suitable for pistol clearing and rifle clearing. And a squib rod or drop weight to test for and remove wads stuck in shotgun barrels. Using one in this case would have been a correct way to get a round that the extractor cannot grab out of the chamber by running the rod from muzzle to chamber. Stick a small rag over the slide face and extractor to make sure the primer of the round does not contact the extractor tip when the cartridge is bumped out of the chamber. Why? Isn't this just a crutch for an ill-prepared shooter? No, it's because a loaded firearm may not be taken from the unloading table (which is the final "station" on the firing line of every stage) until it is cleared, except with direct supervision by a match official. Without a suitable tool to assist a shooter or a match official to clear the stuck round, one of the match officials must find a way to assist the shooter to place that still-loaded firearm into safe condition for temporary storage and transport - maybe even over the public road system. Make it easy to do so - keep clearing rods around the match. good luck, GJ

-

That's disappointing, IMHO. But glad you are seeking better understanding of the rules. GJ

-

No, as a matter of clarification, I did not allude to an answer. I provided the exact spot where the rules state the error and the penalty. The Pocket RO Card is part of the rule book, yes, but it has historically never been the main reference for the rule and penalty. It often lags behind being correctly updated when the rules are changed. It often paraphrases the rule and may be written in shorter form. The RO committee writes/approves the rules, they normally (from my understanding) do not compile the changes to the RO pocket card (an admin function after the rules are approved). good luck, GJ

-

Firearm discharge at the unloading table - rules say Match DQ: Under the Match Disqualification section, page 29 of WB Shooters Handbook: The only possible reprieve would be if the shooter had asked for a match official to assist with clearing the pistol, and they found that the only possible way to clear the gun would be to cautiously BLOCK or lower the hammer, take the pistol to the firing line, and fire it safely downrange with the rest of the posse safely behind the firing line. Then that becomes a supervised firing of the gun downrange, and no penalty is incurred. It is a major failure to attempt to clear a firearm at the unloading table if there is any chance it may discharge. There should never be an idea in the mind of a shooter that cocking and firing any gun at the unloading table is a safe thing to do. And, importantly, I have never seen a case where a well trained range official cannot get the firearm unloaded without it firing. And if there was any possibility of it firing, I would have insisted they do THAT at the firing line with safe downrange conditions. There is NEVER such a level of time or peer pressure at a match that the shooter should consider endangering themself or other shooters or spectators. good luck, GJ

-

Free advice given here is guaranteed (money back) for at least 60 days, so no rush getting it taken care of. 😄 GJ

-

I have given up on trying to use tenon mounts for larger/taller front sights, as have many smiths I know. Tenons just will not hold a heavy sight securely. Pretty easy to have a smith mill a standard dovetail on the front and mount a sight. Then the front as well as the rear is drift adjustable. And MUCH more secure. Perfectly legal for any Wild Bunch shooting. good luck, GJ

-

Gun stainless steel is usually a 41x or 44x series stainless, which IS MAGNETIC. That slide is very different than the common (acid resistant) non-magnetic stainless, like 304 or 316. THOSE are non-magnetic, soft(er), and not amenable to heat treatment due to greatly different alloy content. Nope, your slide is gun-grade stainless, almost certainly. good luck, GJ

-

Nice work. Is that cerakote on the frame now? Nice two-tone vibe. Bigger fixed sights would make it a great carry and WB Traditional gun! good luck, GJ

-

Decide if this is a shooting gun or a BBQ gun. Just that often sets the tone to get you to "perfect". From the mixed pedigree of parts, this seems to beg to be a shooter or daily carry, not a dressed up gun. BUT - What parts you use are really what meets your taste and performance goals. I really like good checkered wood grips on 1911s. Some folks like G10 plastic with real aggressive checkering, if you need the extra-firm locked-in feeling grip. And I like a relief cut for the thumb to reach the mag release easily. (But, my tastes would not run towards any of the 3 sets you show. Just me) I would use the barrel bushing that fits the slide moderately tightly and the barrel moderately tightly. The heck with the "appearance" - I would go for 100% reliable performance and good enough accuracy. If you get 3" groups from rest at 25 yards, be delighted. It's always better for cleaning if the bushing will come out without a bushing wrench, but if I get great accuracy with a tight fitting bushing, I'll put up with always carrying a wrench in my kit. good luck, GJ